- #Fastcam software tutorial pdf

- #Fastcam software tutorial manual

- #Fastcam software tutorial full

- #Fastcam software tutorial verification

By avoiding long pre-heat times especially on heavy materials productivity increases dramatically. EdgeSmart™ (Patented) improvements - Option to allow for starting on the edge of the material to begin the cutting process.Common Cut Nesting & Post nest optimization including Bridging, Tabbing, Chain Cutting & Stitch Cutting.Multi stage corner and hole size deceleration and acceleration in NC output option improves cut quality on corners and small holes.

Small hole option allows for variations in cutting speed & hole avoidance produce nests that can be run unattended.

#Fastcam software tutorial manual

#Fastcam software tutorial verification

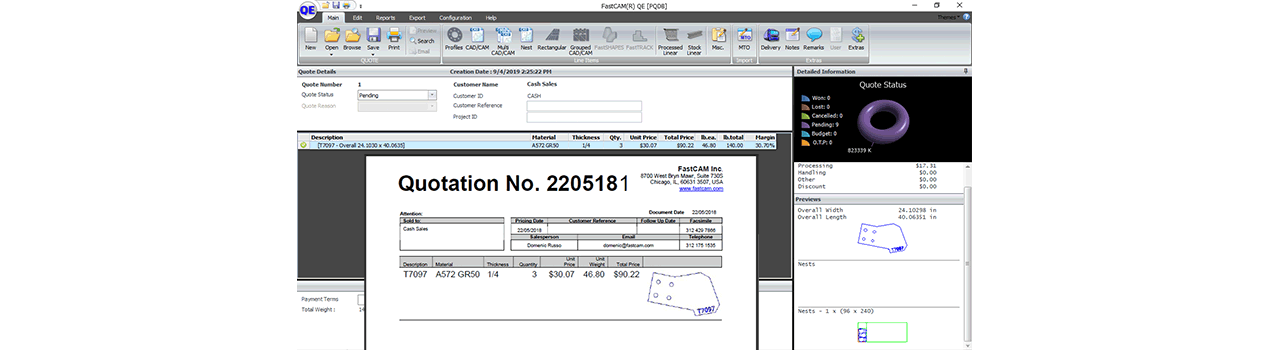

Integrated NC Verification & Code Editor debugs, checks code for collisions and provides Costing data.CAD Tools allow you to import, extract, edit, clean and compress a range of popular digital files including PDF.DXF layer support for different processes.Compatible with most popular cutting equipment and industry standard file formats.Support for all additional machine processes marking, text marking, drilling, multiple torches, multi-torch nesting, multi pass single torch bevel cutting and more.Purpose built: Best Fit, Best Value for Metal Profilers and Fabricators.

#Fastcam software tutorial full

All our FastCAM® Systems include multi process support for cutting, marking, drilling, tapping & full CAD compatibility as well as integrated post processors from our supported list. Packaged and Priced to Suit your Needs and BudgetįastCAM® offers multiple editions to meet the different levels of automation suited to the most common types of metal cutting businesses.

#Fastcam software tutorial pdf

FastCAM® Reads and/or Nests DXF, DWG, DSTV/NC1, StruCAD, IGES and PDF file formats. Where drawing information exists electronically, FastCAM® has an extremely Powerful CAD interface that cleans and compresses code ready for quality cutting. NC output can be Absolute or Incremental. The FastCAM® System is used successfully in Service Centers, Shipbuilding, Mining, Steel Fabrication, Metal Fabrication & Sign Cutting.įastCAM® supports all combinations of machine and controller as well as ESSI, EIA and ISO NC languages in both inch and metric. FastCAM's long experience in heavy plate fabrication makes the system ideal for even the largest construction jobs. Easy Editing & Verification of geometry combined with one step nesting makes the system instantly productive.

0 kommentar(er)

0 kommentar(er)